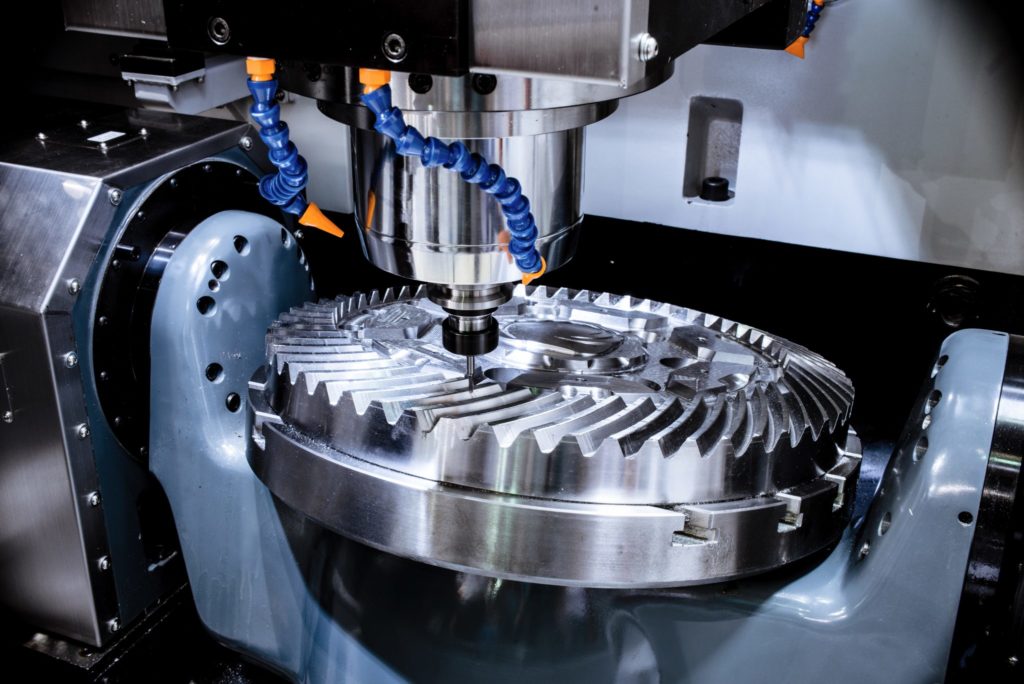

CNC machining is presently perhaps the most ideal methods of assembling high amounts of complex parts and items. There are various key advantages including 24 hour profitability, expanded efficiency per representative, less expensive activity than manual machines and then some. In this short guide we will feature these key advantages. In particular, CNC machining offers an occasion to extend your association’s efficiency to 24 hours every day, 7 days per week. This is on the grounds that CNC machines have around a 99% up time, having the option to be left turned on for quite a long time, many months on end, just waiting be killed incidentally for upkeep. This implies giving you have staff to screen the machines, you can drastically build your association’s creation with 24 hour activity. This expanded working time can be encouraged for various reasons. The first is simply the very idea of CNC machining. Since these machines are worked by PCs, the representative checking them should not be as dynamic.

Accordingly, it is feasible for one worker to oversee three, five or more machines on the double. Let’s assume you have a labor force of ten individuals and ten machines, this implies you can isolate their days of work nonstop over a few days of the week. This implies somebody can screen the machines consistently, encouraging every minute of every day activity. The following thing to know is that these serious machines really require less information to work contrasted with a customary manual assembling activity. Thus, progressed abilities are not, at this point required which as a rule can mean a decrease in worker overheads. CNC machining can likewise be prepared a great deal rapidly and essentially than more established, manual strategies. This should be possible through viewing instructional recordings, utilizing preparing programming or finishing short tests as opposed to the long stretches of educational cost expected to work more seasoned, manual based machines.

One of the most significant highlights of CNC machining gear to entrepreneurs in the assembling area is that more perplexing items and parts can be made utilizing these machines versus more seasoned manual machines and processing Cheshire Seals. This empowers you to enhance your contribution by venturing into different territories you presently do not work in gratitude to the new capacity of delivering new segments for various areas. At long last, a key advantage for your clients is speedier turnaround from CAD attracting to completed item. Because of the intensity of current CAD programming, it is conceivable to recreate assembling of the item without the need of a model or model. When the planner or customer is content with their item, the CAD attracting can be messaged to you for contributing into your machining framework.